Product

Contact Us

+86-538-8989736

High tech Development Zone, Feicheng City, Shandong Province

You are here:Home > Products > Geomembrane

Geomembrane

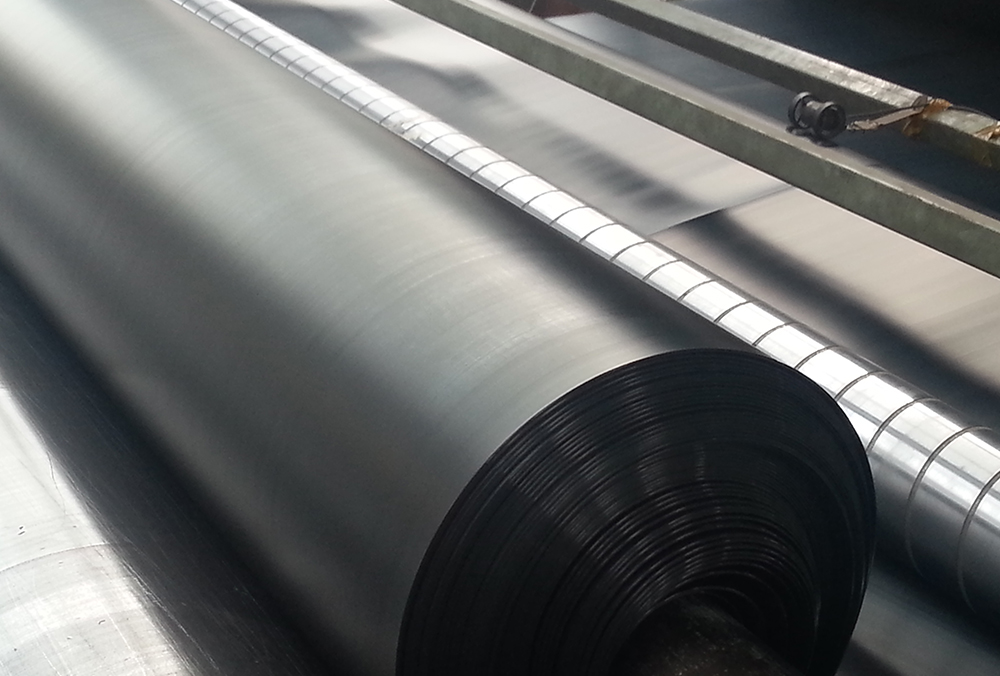

Name of HDPE film "high density polyethylene film has excellent resistance to environmental should stress cracking resistance, low temperature resistance, aging resistance, corrosion resistance, and -60--+60 use of larger temperature range and longer service life (50 years).

Product Details

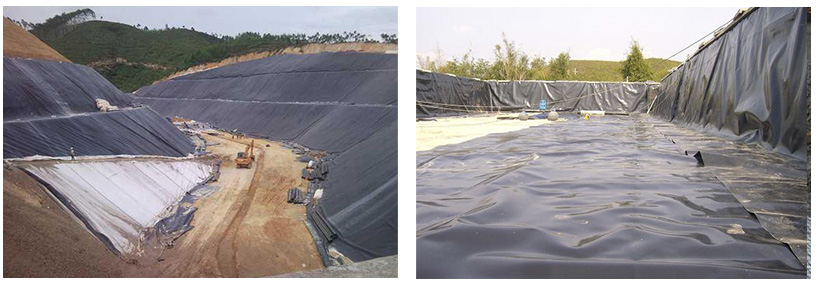

HDPE geomembrane name "high density polyethylene geotechnical membrane has excellent resistance to environmental should stress cracking resistance, low temperature resistance, aging resistance, corrosion resistance, and -60--+60 use of larger temperature range and longer service life of 50 years, widely used in municipal solid waste landfill, solid waste landfill impermeable, sewage treatment plant impervious, artificial lake seepage, such as tailings disposal anti-seepage project.

HDPE geotechnical membrane laying design

1 laying the HDPE film before the civil engineering shall be the corresponding qualified acceptance certificate. 2 HDPE film before cutting, it should be accurate measurement of its related dimensions, and then according to the actual crop, generally should not be based on the size of the cut, should be piece by piece number, detailed record in the special form.

3 when laying HDPE film, we should try to save the raw material as far as possible, at least, in the premise of ensuring the quality. At the same time, it is easy to ensure quality.

4 the width of the joint between the film and the film is generally not less than 10cm, which usually makes the direction of the weld line parallel to the maximum gradient, that is, along the direction of the slope.

5 normally in the corner and abnormal area, should be as far as possible to shorten the length of the joint. In addition to special requirements, the slope is greater than the 1:6 of the slope from the top slope or the stress concentration area of 1.5 meters, as far as possible not to set the weld.

6 HDPE film in the laying, should avoid artificial folds, the temperature is low, should be as far as possible taut, smooth.

7 HDPE film laying completed

technological process

In the process of the construction process, the construction process is shown in the construction process of the composite earth dam of the Zhou tou reservoir dam, which is to take the section of excavation, side paving, edge compaction and edge protection.

Fig. flow chart of seepage prevention construction of geotechnical membrane

Surface cleaning up

Base must be in according to the design requirements of clean, which is key to ensuring that the impervious effect, especially on Chienshih roots and other debris to clean, base not allowed local bump phenomenon, clean the surface to the ramming hammer or tamping plate rammer tight, the dense formation.

Composite laying film, be sure to be up and down and laying. Between membranes and membrane and the surface between trying to flatten out close to, but not the film pulled too tight, general slightly loose a little, but not at the bottom of the film left bubbles. Because geomembrane is thin and very light, paved, unpaved protect layer can easily be blown by the wind, so a PU membrane area is not large, the best side of the laying of the membrane side cover protection layer soil.

According to the information provided in Shenzhen bluegrass, composite geomembrane width of 1.0~1.9m, with 1.9m width of this project, in order to reduce joint materials. Joints are hot sticky, adhesive, lap and other methods, the project design using adhesive, seam width 50mm.

If it is found that the geomembrane punctured or torn place, must use three times in a damaged geomembrane adhesive area fill.

Protective cover

By geomembrane 10cm thick protective layer soil material must pass through a sieve, is not allowed to have a diameter greater than 6mm particles; otherwise, it is easy to stab a ground breaking film. Protection layer soil material must be used to make compaction, to ensure that the dry bulk density of 1.5 or more, and at any time sampling inspection. The backfill protection layer and masonry block stone revetment, must handle with care, to avoid hitting ground breaking work film. In the rubble mound below should be laying and filling 100mm thick gravel or crushed stone cushion to prevent because of changes in the water level, the influence factors of wind and wave and scouring soil material protective layer. Dry masonry block stone take the artificially hanged line paving stones should be tightly embedded solid, surface stone individual weight should be greater than 48kg, all the gaps were used small piece of stone filled fill.

Peripheral processing

Peripheral junction processing requirements of the composite geomembrane and the soil around tight junctions, seepage blocking the entrance, truncated lateral leakage path to prevent water seepage into the bottom of the geomembrane, blister formation, in the drawdown of reservoir water swelling ground membrane. Therefore we must dig trenches around the junction, and the geomembrane embedded groove.